SOLUTIONS FOR EFFICIENT & OPTIMIZED STORAGE MANAGEMENT

Along with our Technology partners, we develop projects for the storage and transport of materials in various sectors such as port terminals, mining, cement, steel, power plants, fertilizers, Oil&Gas, or agri-food. We offer complete technological solutions from the feasibility stages to the start-up of the facilities.

Core Competencies

Consulting

Maintenance

Project Management

Automation & Digitization

Engineering & Procurement

Erection

Commissioning

Retrofitting & Modernization

Training

After Sales Service

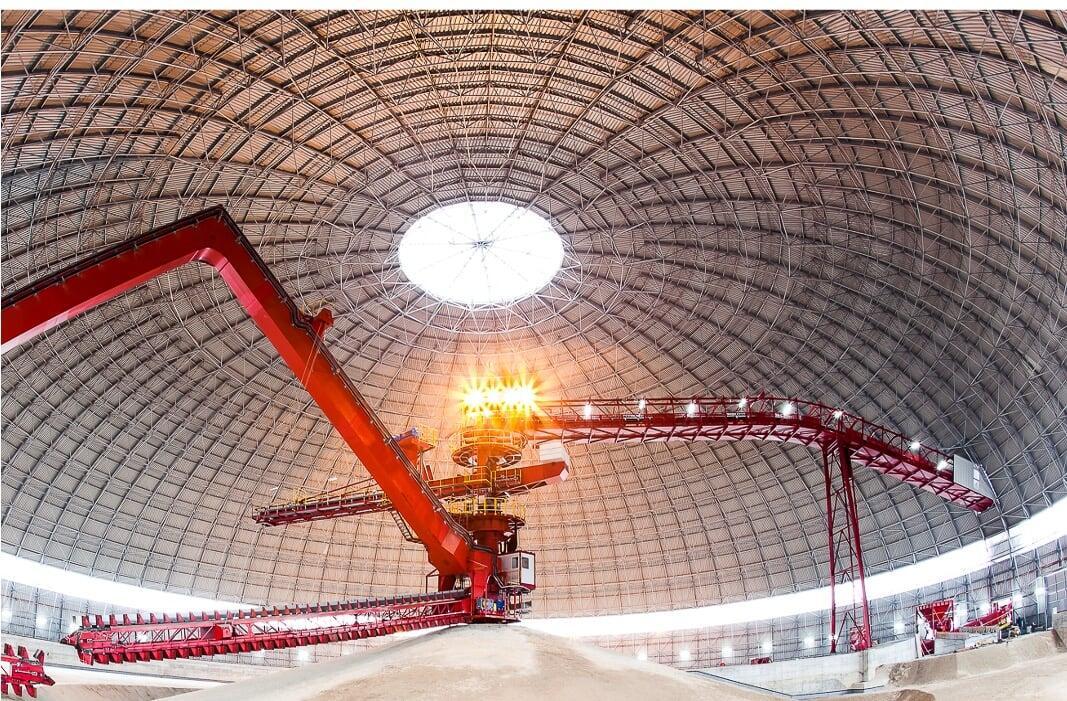

STOCKYARD TECHNOLOGY –

EFFICIENT MACHINES FOR OPTIMAL STORAGE MANAGEMENT

STOCKYARD SYSTEMS

- Marine Loading Arms

- Stackers

- Semi-Portal Scrapers

- Portal Scrapers

- Side Scrapers

- Slewing Scrapers

- Bridge-Type Reclaimers

- Bucket Wheel Reclaimers

- Stacker-Reclaimers

- Circular Stacker-Reclaimers

- Loading Systems

- Conveying Systems

- Individual Solutions

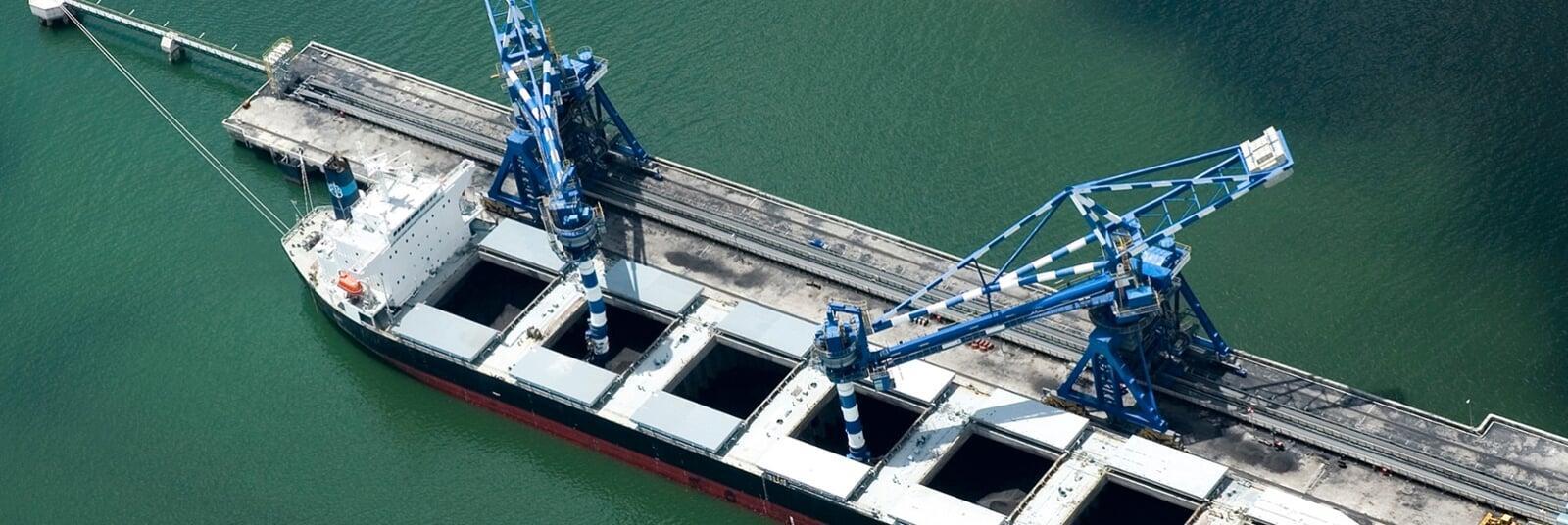

PORT TECHNOLOGY –

INDIVIDUAL MACHINES FOR EACH PORT

STOCKYARD SYSTEMS

- Shiploaders

- Ship Unloaders

> Quadrant radial-type shiploaders

> Ship loaders with gravity spiral chute for loading

bagged goods.

- For bulk materials unloading, two types of handling systems are basically deployed: continuous and discontinuous. We offer:

- Grab-type unloaders with a movable superstructure and a single-link or double-link luffing boom.

-Grab-type unloaders with rail-mounted portal bridge.

CONVEYING SYSTEMS –

FROM MINING TO PRODUCT SHIPPINGPRODUCT SHIPPING

CONVEYING SYSTEMS

- Belt Conveyors

- ChainConveyors

- Drive Stations

- Shifting Heads

- Tripper Cars

- FeedingHoppers

- Hopper Cars

- Components

LOADING & UNLOADING SYSTEMS -

SOLUTIONS FOR THE BULK HANDLING

CONVEYING SYSTEMS

- Truck Loading

- Train Loading

- Wagon UnloadingUnloadingUnloading

- Train Loading

- WagonUnloadingUnloadingUnloading

- WagonDefrostingDefrostingDefrosting

- Automatic train loading systems enable continuous

loading of railroad wagons. During loading, the fill level is monitored by ultrasonic sensors. When the desired fill level is reached, the knife gate of the hopper outlet opening automatically closes.

Need Solutions for Port Management?