Tubes & Pipes

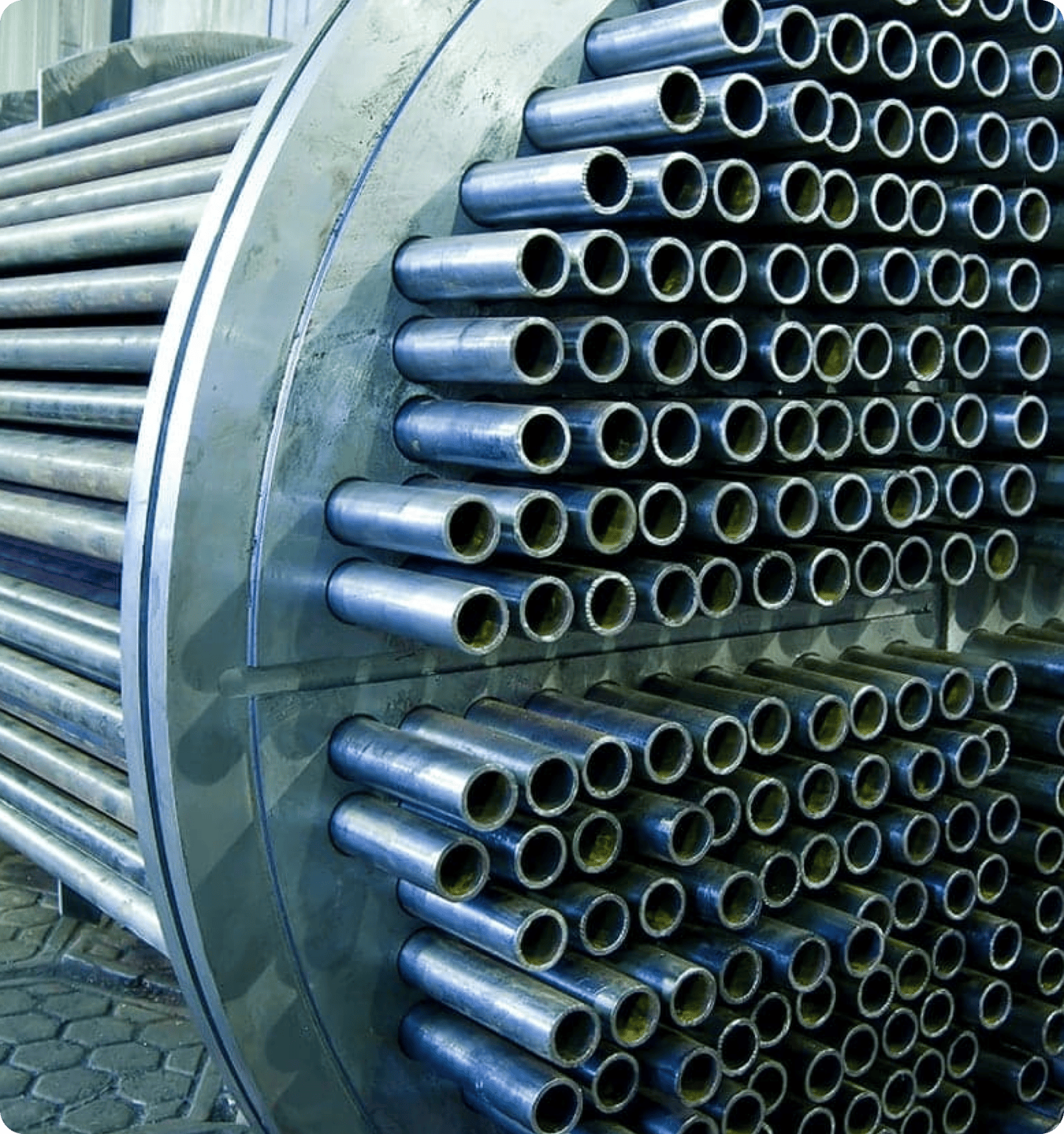

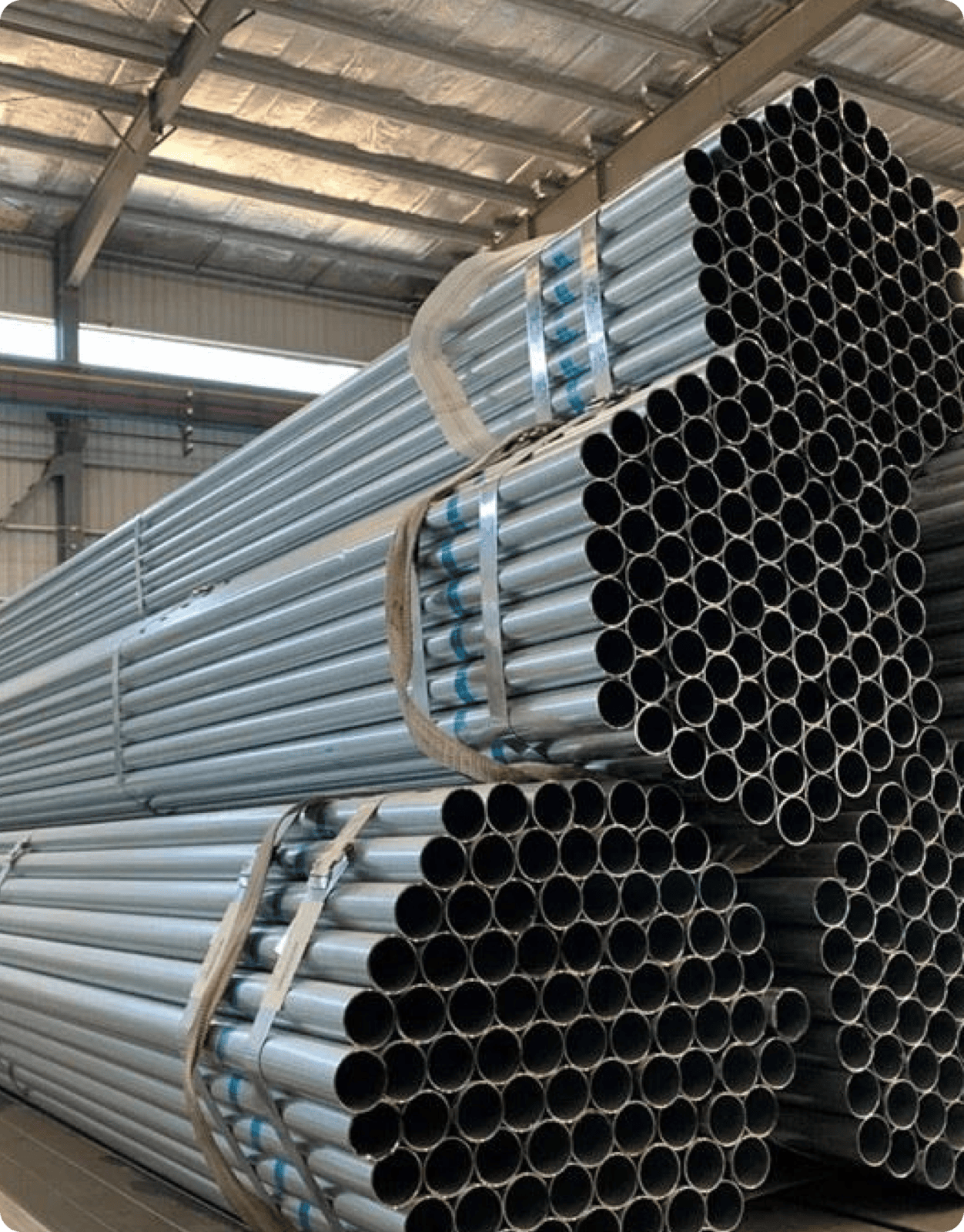

As a SABIC APPROVED premier manufacturer, Higron specializes in producing a wide range of seamless tubes and pipes, including carbon steel (CS), alloy, and stainless steel (SS) variants. With a relentless dedication to precision engineering and customer satisfaction, we set the bar high for excellence in the industry.

Higron manufactures 18000 Ton per annum of cold drawn seamless tubes with state of art manufacturing facility spread over 40,000 square meters in Ahmedabad, Gujarat, India and export high-Quality Straight and U Bend Tubes and Pipes to Asia, Middle East and Africa. As a trusted manufacturer and exporter, we serve clients worldwide, delivering our premium products to markets across the globe. Our extensive distribution network and strategic partnerships ensure timely delivery and seamless logistics, regardless of location.

Applications

Oil refineries

Heat exchanges

Boilers

Petrochemicals

Pressure Vessels

Steel plants

Condensers

Heaters

Fertilizers

Carbon Steel Cold Drawn Seamless Tubes And Pipes

Straight & U Tubes

Stainless Steel Cold Drawn Seamless Tubes And Pipes

Straight & U Tubes

Alloy Steel Cold Drawn Seamless Tubes And Pipes

Manufactured as per various standards

Fin Tubes

Multiple types of including G, L, KL Fin etc.

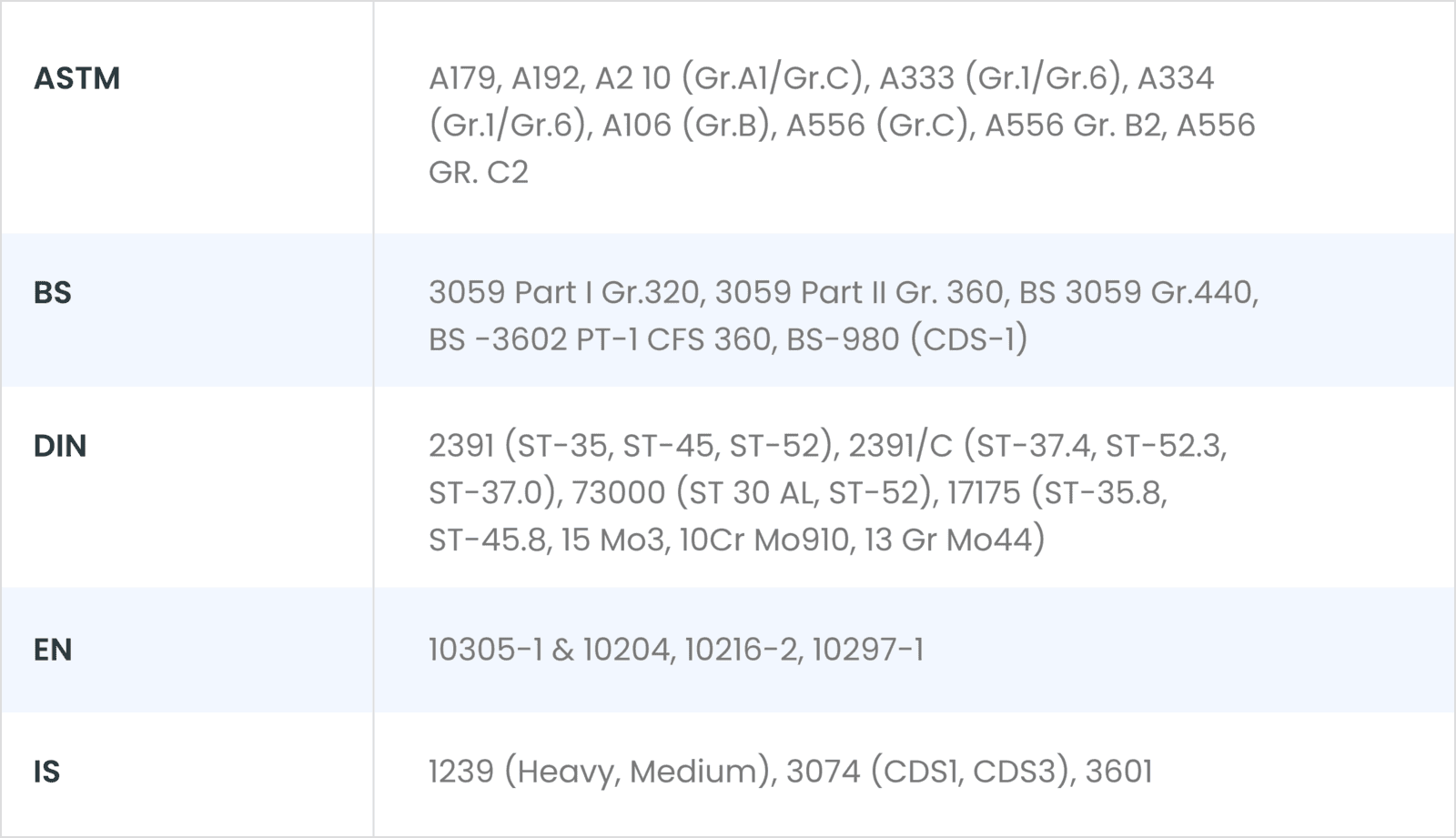

Carbon steel Cold Drawn Seamless Tubes And Pipes (Straight And U Bend)

Manfacturing Range

Diameter: 4.0 MM TO 220 MM

Thickness: 0.5 MM TO 25 MM

Length: UPTO 31 MTRS

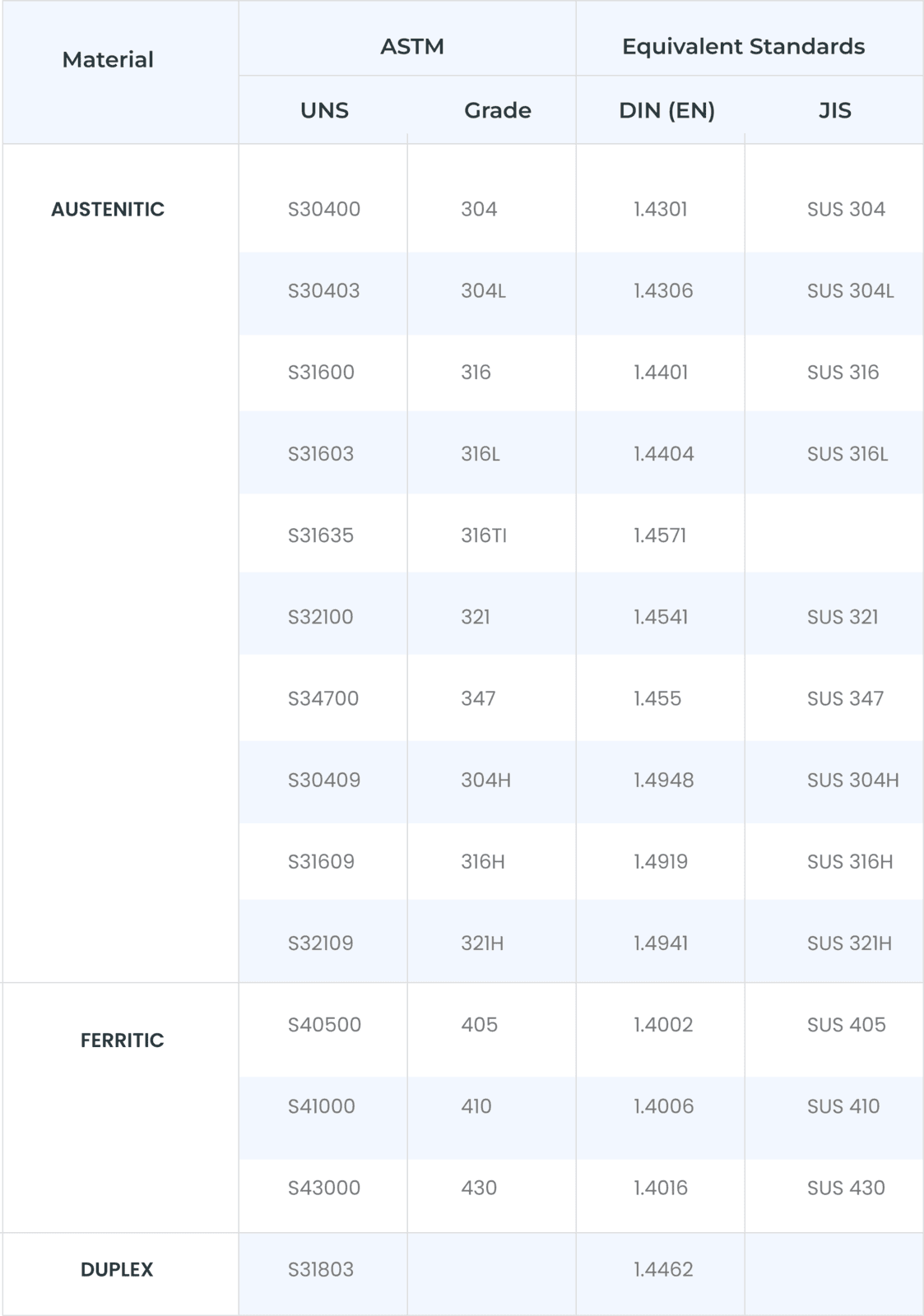

Grades & Specifications

Stainless steel Cold Drawn Seamless Tubes And Pipes (Straight And U Bend)

Products

Stainless Steel Cold Drawn Seamless Straight & ‘U’Bend Tubes & Pipes.

Welded Stainless Steel Tubes & Pipes

Bright Annealed Tubes & Pipes

Manufacture Range

Diameter: 4.0 MM TO 220 MM

Thickness: 0.5 MM TO 25 MM

Length: UPTO 31 MTRS

Grades & Specifications

Alloy steel Cold Drawn Seamless Tubes And Pipes (Straight And U Bend)

Manufacture Range

Diameter: 4.0 MM TO 220 MM

Thickness: 0.5 MM TO 25 MM

Length: UPTO 31 MTRS

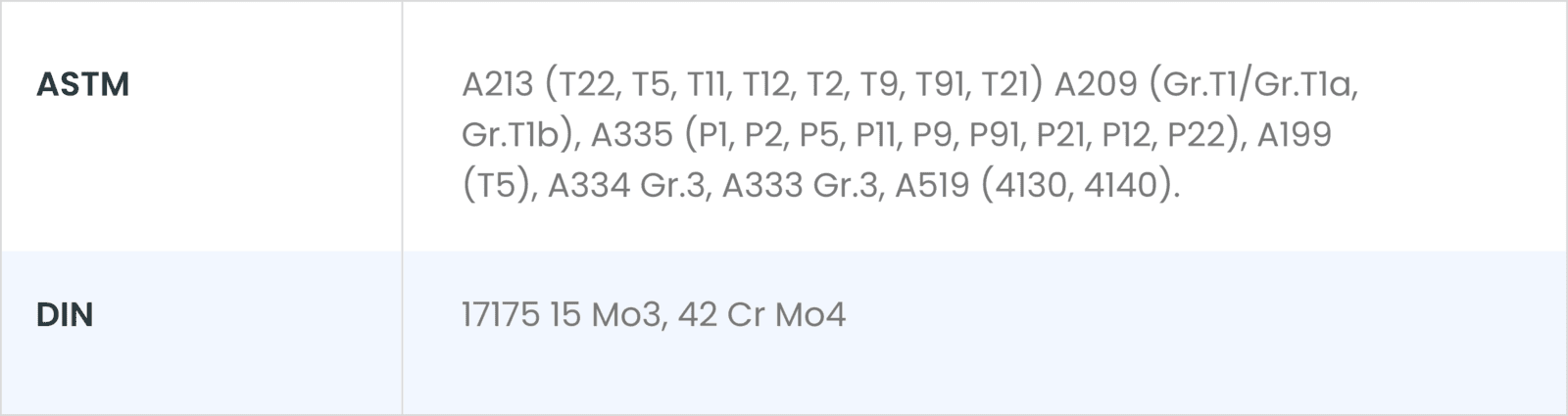

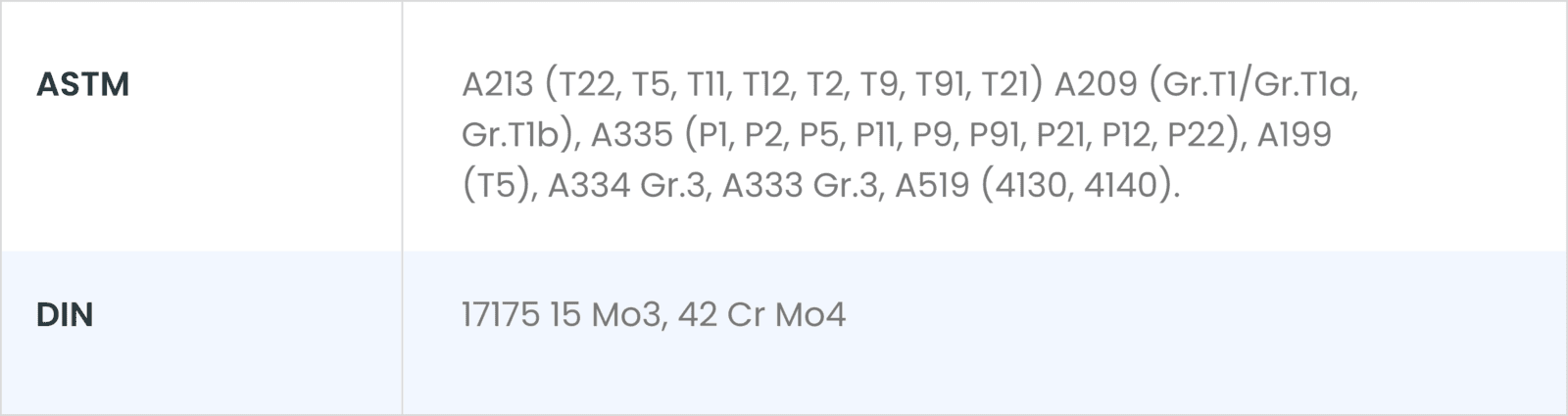

Grades & Specifications

Welded Tubes And Pipes (Straight And U Bend)

Manufacture Range

Diameter: 4.0 MM TO 220 MM

Thickness: 0.5 MM TO 25 MM

Length: UPTO 31 MTRS

Grades & Specifications

Fin Tubes

Products

Diffrent Type Of Fin Tubes

Extruded Aluminium Fin Tubes(bimetallic Fin Tube),

Helically Wound High Fin Tubes

‘G’ Fin (also called Embedded Fin or Edge Grooved Fin )

L’ Fin(Also called shoulder Tension Fins , Wrap on Fins ),

KL’ Fin (also called knurled ‘L’ Fins)

Integral Low Fin Tubes

Manufacture Range

Fin Thickness: Minimum 0.8mm to maximum 3 mm

Fin Height: Minimum 0.25″(6.35 mm) to 1.5″(38 mm)(depending on the bare tube outer diameter on which fining is to be done)

Fin Density: : Minimum 46 fins per meter to maximum 287 fins per meter(depending of the thickness)

Material: Carbon steel, stainless steel (304,316,310,410,321,347 ect), alloy steel(P5,P9,P11,P22 ect.) inconel,high chrome,high nickle & incolloy (any ferrous material)

Tubes Diameter: 30mm OD minimum to 220mm OD maximum

Tube Thickness: Minimum 2 mm

Tube Material: Carbon steel,stainless steel (304,316,310,410,321,347 ect), alloy steel(P5,P9,P11,P22 ect.) inconel,high chrome,high nickle & incolloy (any ferrous material)